Greatest Works

Helix Engineering.

Simplicity in Compressed Air Systems is what we do. We provide the most efficient, reliable and complete solution for your compressed air requirements.

INVERTER DRIVEN SCREW COMPRESSORS

- The IVR drive selected is the world’s leading brand, and is built into the machine. Compressor with asymmetric screws. High efficiency, high output and low noise level.

- All data displayed in standardized symbols Built-in IVR for compressor speed variation and ramped motor startup, including standard RFI filters.

- IVR machine varies capacity to suit your air demand for saving power.

- Built-in IVR drive for maximum reliability.

- Factory-tested machine at critical speed to minimize vibration/resonance risk.

- Eliminates unloading power to almost 0%

- Ensures fastest payback.

- Promises lowest operating cost

Regulates pressure within 0.1 bar. - Assures constant power factor.

- Assures reduced carbon dioxide emissions saving environment

Generally during a life cycle cost of the compressor , more than 80 % depends majorly on Power.in Todays environment where uncertainity in production is more, companiesneed to keep operational costs low to stay profitable. Major part of running cost is the power bill. Keeping that in mind Chicago Pneumatic Variable Frequency Drive Compressors/Inverter Drive Compressors (VFD/IVR) compressors can save over 35% power and consume less energy, thus ensure you big savings and is environmental friendly.

IVR compressors from Chicago Pneumatic operate optimally under any variable load conditions and ensure maximum capacity with minimum consumption. All components are reliable, efficient and time-proven, and are the standard components used in traditional machines.

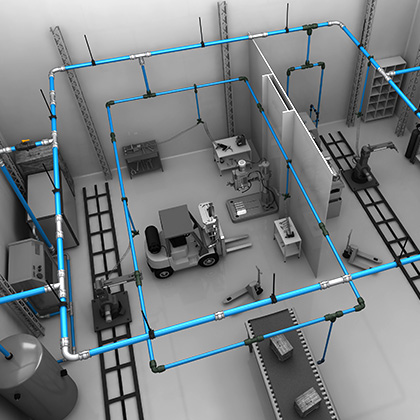

PNEUMATIC MODULAR PIPE LINE

- Helix Provides entire range of Pneumatic products from Point of generation to point of application i.e Air Compressors to Pneumatic Pipe line system.

- The air compressor piping in your system can make or break the profitability of your enterprise. Lost power through inefficient or faulty piping can wipe out your profit margin and give your competitors an advantage. Pay attention to the layout, installation and maintenance of your compressed air piping system to control costs and keep your business in green.

- A major drawback of getting all of your compressed air from one source is that you end up sacrificing simplicity in your piping system. All too often, planning the compressed air piping system is the last consideration when organizing a shop floor.

- We are into Right Consultation / installation/commissioning of Aluminium modular piping system which is a fast, easy and reliable. Designed for compressed air, vacuum, and other inert gas applications from the source to the point of use with the lowest total cost of ownership.

- The pipes and seamless connections have superior sealing to prevent leaks and reduce friction to a minimum. This prevents pressure drops, saves energy and contributes to the sustainability of your production.

We support the dynamics of your business by providing comprehensive product range which gives the flexibility to use the system for a wide range of applications. It can be connected to any existing network within no time & its modular technology gives you the advantage of modifying / expanding your network without affecting your production.

Our Compressed Air Piping System requires no welding and thus can be installed quickly and easily, compared to conventional and outdated installation methods.

If you look at your total cost of ownership, Right Compressed Air Piping Layout will turn out to be the best investment choice you can make. Piping network is engineered to support sustainable operational excellence in your production process. Material and product design, installation and maintenance costs, flexibility and safety – they all influence your total cost of ownership and the level of efficiency in your production. Hence we are here to give you consultative approach in providing best in Industry Products and make you future ready.

SCREW COMPRESSOR RANGE

- Reduced energy consumption for optimum output.

- High product efficiency.

- Cost savings on maintenance and energy consumption.

- PLC based standard controller.

- High quality components ensures maximum longevity in operating conditions.

- Easy access to every service points.

- Designed for 46°C ambient temperature.

- The oil-free compressed air generated by our compressors comply with ISO class 0 (class zero), i.e. ISO 8573-1. This means that there is no risk of any contamination caused by the compressed air production.

A rotary screw air compressor is a positive displacement compression system that includes a pair of matching helical screws. An oil-flooded rotary screw compressor includes a lubricant that fills the gap between the rotors, which creates an air-tight hydraulic seal and transfers mechanical energy between the two rotors. The air moves through the threads as the screws rotate, and the meshing screws force the air through the compressor

Chicago Pneumatic range of screw compressors are engineered for high performance ,effeciency and reliability which can meet the demands of various industrial applications. With an option of Floor Mounted Unit and a Tank Mounted Unit , Chicago Pneumatic Make is one of the most compact and rugged machine in the industry today.

The CPM Chicago Pneumatic Compressor product line includes 3 HP, 5HP & 7.5 HP screw air compressor models that include a long-life V-belt drive, high efficiency intake filter and a robust TEFC motor. The standard quiet enclosure is designed to reduce vibration and noise levels. This specially designed compact model features a low oil carryover. An integrated dryer and tank mount option is also available.

The CPA Chicago Pneumatic Compressor product line includes 10HP,15HP,20HP rotary screw air compressor line is specifically designed to provide reliable compression in the most challenging applications. The ES4000 controller enables the compressor to operate with maximum efficiency. With low sound level , you’re assured of quiet operation. The CPA Range is also designed for easy serviceability. Its also provided with an additional Magenetic Pre Filter Panel to take care of excess dust particulate , hence designed to run in rugged conditions.

The CPB Chicago Pneumatic Compressor Product line includes 15 HP,20HP,25HP,30HP,40HP Rotary Screw Air Compressors regarded as among the most reliable models you’ll find anywhere. The Pressurized Canopy design ensures optimum cooling of machines and gives a longer machine life. The CPB Models are also availablle with VFD Option and ES3000 Controller to take care of varying load conditions.

The CPC Chicago Pneumatic Compressor product line includes 40HP,50HP,60HP Rotary Screw Air Compressors which is also available with high performance variable speed option that can be used in a wide range of applications. All CPC Range units feature industry leading efficiency and serviceability. The models can be configured as basic units or can be equipped with some basic options to best fit your application. All CPC models have low sound levels, small footprint and the lowest total cost of ownership in the industry. We have an option of configuring these models with IOT Devices to ensure the machine is connected with the user at all times, thus ensurinng the lowest down time.

The CPD Chicago Pneumatic Compressor product line starts from 75 HP onwards which is again available with high performance variable speed option that can be used in a wide range of applications. We have an option of configuring these models with IOT Devices to ensure the machine is connected with the user at all times, thus ensurinng the lowest down time. The premium effeciency IE3 motors used ensure highest effeciency and reduced power consumption.

We also have a Range of 100% OIL FREE Compressed Air Solution. Applications that are sensitive to any kind of contamination in the compressed air supply require an oil-free compressor for compressed air generation.Clear examples of such applications are met in medical, dental and pharmaceutical industries, as well as in the food and beverage industries. Nevertheless, industries like chemical, electronics, oil & gas and textile use also oil-free compressors. Eventually, oil-free compressed air is a requirement for PET bottle blowing, textile processing and in farming for milking.

The oil-free compressed air generated by our compressors comply with ISO class 0 (class zero), i.e. ISO 8573-1. This means that there is no risk of any contamination caused by the compressed air production.

Depending on the air consumption, we offer you 3 ways to generate oil-free compressed air. For small applications like dentists or in breweries where no continuous demand is needed, a “CleanAIR -OIL FREE PISTON COMPRESSOR” can be used. Medium applications like milk robots in farming do not consume that much air, but may have to run continuously. Consequently, our “SpiralAIR-SCROLL COMPRESSOR” is the ideal choice. For larger applications that use bigger amount of compressed air over a longer period of time, the range of “WisAIR compressors- WATER INJECTED COMPRESSOR” offers the perfect solution.

OIL FREE & PET COMPRESSORS

PET COMPRESSORS ( HIGH PRESSURE COMPRESSORS )

- Chicago Pneumatic offers 100% oil free quality air supplying compressors specially for PET blowing industry ranging from 55 CFM TO 1200 CFM at 42 Bar pressure. The wide range of standard or customized model are designed for 24 hours’ operation, years after years.

- It is an advanced 100% oil-free reciprocating compressor air system. Totally engineered, plant tested, proven in performance. Comes with a built-in water/air cooling system. Needs no foundation, Requires very little time and labour in installation. Ready to use. Just plug in to the power outlet. And enjoy quality compressed air

- The PET bottle blowing compressors that we manufacture are among the most energy efficient on the market. Being oil free means no expensive air filters must be replaced and that there is no energy loss due to these filters pressure drop.

- All our compressors are installed with a ICON system which safeguards the performance of our customers’ equipment. ICONS links all your compressors with your smartphone and/or computer. It allows continuous monitoring and analyzation of efficiency and allows making accurate and immediate improvements when needed. In case of service due ICON will warn you ahead of a shutdown or similar, this way you can avoid the risk of a breakdown. Additionally, the transparency facilitates assessing system performance leading to improved system usage and minimizing energy consumption costs.

100% OIL FREE AIR COMPRESSORS

- CHICAGO PNEUMATIC Oil Free Air Compressors ensures quality & purity in the compressed air to meet the demands of industries where the air quality is vital. This series can serve industries like Power plants, Oil & Gas. Textile, Pharmaceutical, Food & Beverages, Cement and many more

- Available in Option of Inbuilt VFD , Air Cooled and Water Cooled Model . Air Cooled versions which is also known as self contained units are recommended where the water quality is an issue.

- Advanced design of CP Compressors reduces friction load. Excellent cooling and low inter-stage temperatures increase the life of the machines. Being 100% Oil Free Compressors , It eliminates the risk of oil contamination to your process and minimize the risk of operational downtime. The rugged machines are built to operate round the clock for all your oil-free high pressure applications.

- Totally integrated package with proven piston technology comes as a plug and play unit .The Acoustical Canopy consist of simple drop in panel with fire retardant and sound absorbing material makes work environment pleasant with extremely low noise level. This dynamically balanced model with very less vibration comes with a unique base frame which is a PATENTED design and requires no foundation. The machine is also provided with a unique PATENTED 3 part belt design for easy assembly and dismantle during overhaul/service, hence ensuring quicker uptime.

- The machine is provided with 5th Generation microprocessor control which adapts to your air requirement and ensures process is extremely flexible and efficient. Stepped Control- Double acting cylinders allows the flow to be adjusted by clamping one or several suction valves in the open position. Stepped capacity control of 0-100% is possible with more advanced control as per process requirement. Bypass- The use of Pressure control valve gives an extremely stable pressure. Narrow pressure band gives flexibility to deliver the performance at optimum regime. Variable Speed Drive- Oil Free Compressor with double acting cylinders Variable Speed drive (VSD) capacity control allows step less capacity control, optimizes energy consumption and ensure process stability.

- All our compressors are installed with a ICON system which safeguards the performance of our customers’ equipment. ICONS links all your compressors with your smartphone and/or computer. It allows continuous monitoring and analyzation of efficiency and allows making accurate and immediate improvements when needed. In case of service due ICON will warn you ahead of a shutdown or similar, this way you can avoid the risk of a breakdown. Additionally, the transparency facilitates assessing system performance leading to improved system usage and minimizing energy consumption costs.

ACCESSORIES & SPARE PARTS SERVICE

SPARE PARTS & SERVICE:

- HELIX Deals with Genuine Spare Parts for all the machines we deal, thus ensuring longetivity of the machines and inturn reduce major breakdowns. Commitment to our customers is the major driving force of HELIX. We have well trained team to manage the After Market queries and to attend to on time.

- We provide AMC and Comprehensive Contracts for all our products. Our service engineers do not restrict to fixed services in a year but they stretch themselves to provide service whenever there is need, be it maintenance or breakdown

ACCESSORIES

- “Refrigeration air dryers” are designed and manufactured to suit the high temperature condition of Asian region considering the 450C ambient temperature and 550C inlet temperature. Sizing of coolers, evaporators with suitable refrigeration components help in this regard.

- In a compressed air system, pressure drop costs money and restricted flow creates problem in applications. The unique, indigenously designed 3-in-1 evaporator facilitates low pressure drop: lesser than 0.2 bar, while providing maximum heat transfer efficiency.

- “Desiccant dryers” can provide pressure dew point as low as -40 Deg. When lower dew points are required, the use of heatless dryers is warranted especially for applications such as Pharmaceuticals,Medical Gases,Electronic Components,etc.

- Dew point based swing control is the unique feature,reducing purge losses when you are monitoring the dew point.

- Digital display showing detailed function of the dryer provided along with Stainless Steel NRV

- “CHILLERS” -We Supply & install Chillers that are designed with closely matched compressor/refrigerant circuit Combinations with temperature control accuracy of ±0.1-0.3°C.

- These chillers are efficient, silent, easy-to-maintain and have low operating costs making them the first choice for numerous applications.

- Chillers are wit built in flow switch which can output protection signal with low flow alarm,over heat & low temperature alarm.

- ” VFD Retrofit Kit”-VFD is needed for the compresed air system as the discharge pressure varies depending on the air flow deman at the application. Hence VFD optimises the discharge pressure of compressor. Power savings has been a major criteria in the industry now and to ensure that you reduce your operational cost , we recommend you retrofit your old machines with VFD.VFD is an electronic module which changes the frequency of the motor to vary the rpm which inturn saves you on power.are available in a different range starting from 20 cfm upto 2500 cfm. As purification of compressed air is very vital , we provide the option of Pre Filter , Post Filter and Carbon Filters.

- ” AUTO DRAIN VALVES”– Condensate drain valves remove condensate from the air system without losing excessive compressed air and without shutting down the system. Condensate can have harmful effects on a system when not removed. For instance, moisture can wash lubrication from air tools and production equipment causing downtime and maintenance; an inconsistent supply of dry air can cause production quality problems; and excessive rust and scale can form in the air distribution system. Also, water can back up into the compressor and wreck the machinery, air dryers can become overloaded, and in-line filters can be destroyed.

- ” VFD Retrofit Kit”-VFD is needed for the compressed air system as the discharge pressure varies depending on the air flow deman at the application. Hence VFD optimises the discharge pressure of compressor. Power savings has been a major criteria in the industry now and to ensure that you reduce your operational cost , we recommend you retrofit your old machines with VFD.VFD is an electronic module which changes the frequency of the motor to vary the rpm which in turn saves you on power.